Process

Introduction

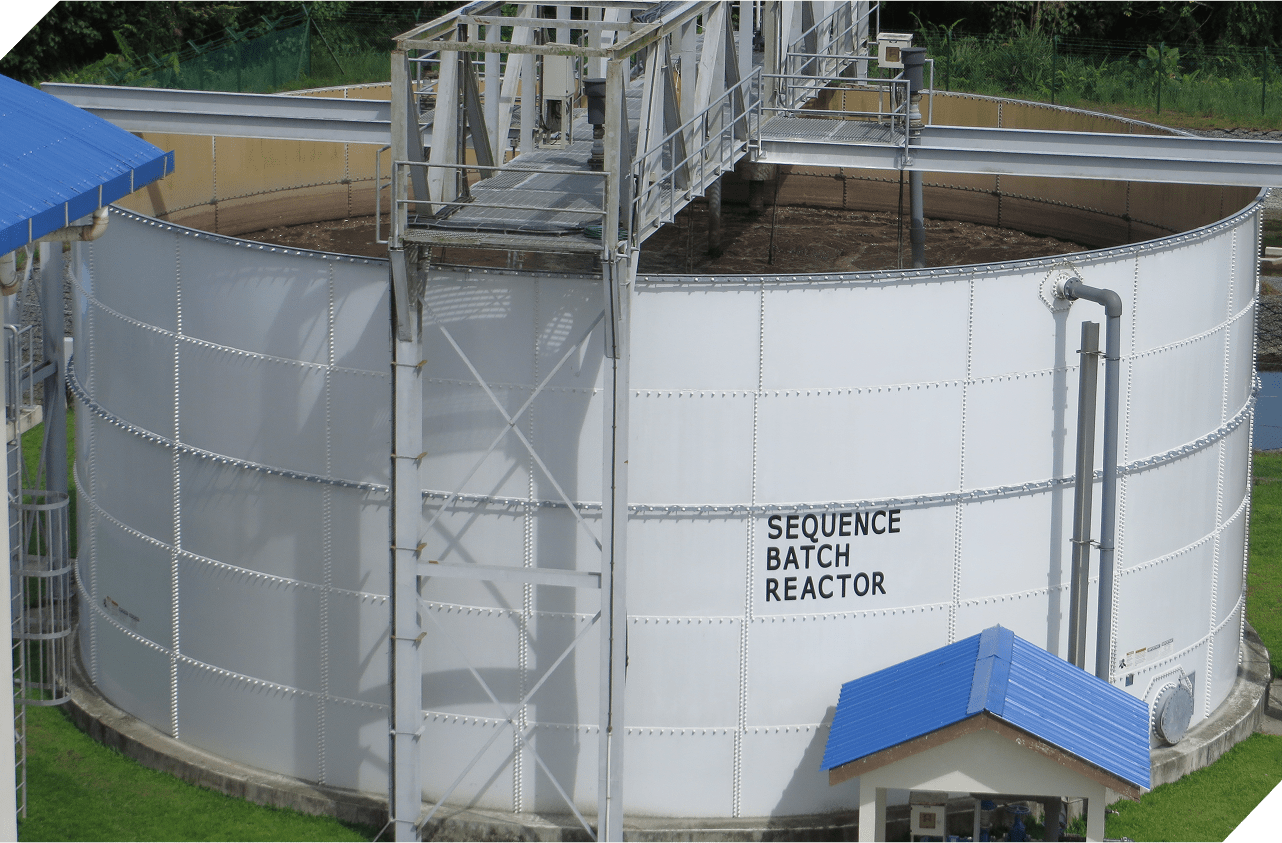

Both the Septic Sludge Treatment Plants (SSTP) in Kuching and Sibu adopt the activated sludge process to treat municipal wastewater. Raw septic sludge, which is collected and delivered to the SSTPs, is dewatered mechanically to remove solids and extract wastewater. The extracted wastewater is then biologically treated in the Sequence Batch Reactor.

Septic Sludge Treatment Plants

Septic Sludge Treatment Plants play a crucial role in enhancing the efficiency and sustainability of the municipal wastewater management system in Sarawak. The effectiveness and reliability of these facilities in treating municipal wastewater improve sanitation, safeguard public health, and promote a cleaner and healthier living environment for local communities.

Septic sludge is pumped from septic tank using a vacuum tanker.

Step 1:

Septic sludge are screened to remove coarse materials and grits.

Step 2:

Septic sludge is mechanically dewatered to remove the solids and extract wastewater.

Wastewater is treated biologically at the Sequence Batch Reactor.

Treated wastewater is discharged into polishing ponds to ensure that effluent quality meets Environmental Quality (Sewage) Regulations 2009 Standard

Dewatered sludge is stabilized with a liming agent to kill pathogen, increase pH and reduce moisture.

Treated sludge is sent to landfill.

Miri Septic Sludge Treatment Plant treats raw septic sludge by breaking down organic matter biologically in the Sequence Batch Reactor (SBR) first, before mechanically dewatering the waste activated sludge from the SBR. The wastewater extracted is returned to the SBR for treatment.